The da Vinci bridge fascinates anyone interested in building and design. Leonardo da Vinci’s bridge can be built using simple materials, and many people have proven its strength and stability in real-world tests.

This article explains how the bridge works, what makes it unique, and how to build your own. It includes insights from real projects and engineering studies like MIT’s test of Leonardo’s bridge design.

People are amazed that this historic design does not need nails, ropes, or glue. Its clever use of interlocking pieces lets anyone create a strong model or even a full-size bridge.

If you want to see ancient ideas come to life, you’ll find practical tips and interesting facts about the da Vinci bridge here.

Understanding the da Vinci Bridge in Real Life Through Historical and Engineering Perspectives

The da Vinci bridge in real life shows the combination of engineering innovation and practicality from the Renaissance period. The bridge’s design relies on carefully using wooden logs and mechanical principles.

This method allows quick assembly without nails or glue.

Leonardo da Vinci’s Original Bridge Design and Historical Context

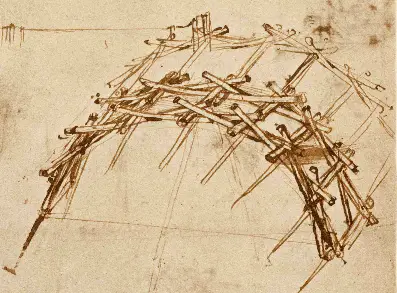

Leonardo da Vinci first drew his famous self-supporting bridge in 1502. He proposed the design for Sultan Bayezid II of the Ottoman Empire.

Da Vinci’s bridge was meant to span the Golden Horn in Istanbul, stretching about 280 meters. This remarkable bridge design would have been the longest in the world then.

The main feature was a flat timber arch that relied on gravity and tight-fitting parts. Leonardo’s historical design is often considered ahead of its time because it used modular assembly and didn’t need modern tools.

The original Istanbul bridge proposal was never built. However, the design has inspired many experimental builds and educational projects worldwide.

This shows Leonardo da Vinci’s lasting influence on engineering and architecture. MIT engineers say the concept also deals with real-world feasibility and construction challenges.

Renaissance Engineering and Architectural Ingenuity Behind the Bridge

During the Renaissance, architects and engineers pushed the limits of design and construction. Leonardo da Vinci’s bridge clearly shows this architectural ingenuity.

He used a modular construction technique, allowing builders to assemble each piece easily on-site. Each wooden log connects through carefully shaped notches and channels.

This system enables the bridge to distribute weight evenly. Although the design did not rely on advanced materials or modern fasteners, it still achieved impressive feats in load-bearing capacity and durability.

Modern builders can learn from Renaissance engineering solutions to solve structural problems with limited resources. The da Vinci bridge is a strong example of innovative design principles and a focus on efficiency, practicality, and strength.

The Concept of a Self-Supporting Bridge Using Wooden Logs

The da Vinci bridge is self-supporting because it stays together due to the careful placement of its wooden logs. Each log supports the next, creating a locked structure without glue, nails, or ropes.

As each piece presses against its neighbors, the bridge gets stronger under load. This method allows for quick assembly and disassembly, which makes the design practical for military use and temporary crossings.

Today, this technique is often used in public demonstrations and educational projects. It helps teach about mechanical principles, such as gravity-based locking and stability.

Simple tools are used, and the construction process can be finished quickly. This is part of why it is so popular in hands-on learning.

Mechanical Principles of Friction and Gravity in the Bridge Structure

The stability of the da Vinci bridge depends on friction and gravity. Each log sits at an angle, and the structure’s weight increases the pressure between the logs.

This friction prevents slipping and keeps the bridge rigid under load. Gravity locks the wooden logs in place.

As weight is added, the bridge presses more tightly together. This makes the structure stable, even as people walk across it or if some foundation settlement happens, as MIT engineers’ modern tests prove.

Using basic mechanical principles is vital to the bridge’s lasting appeal. It shows how simple ideas can have real applications in solving structural challenges.

The Role of No Nails or Glue in Ensuring Structural Stability

One of the most interesting features of the da Vinci bridge in real life is its construction without nails or glue. Instead, stability relies on the precise fit and arrangement of wooden logs.

The mechanical pressure from each part supports the others, making the bridge stable and safe for use. This method gives the bridge several advantages:

- Easy to build and take apart: Useful for armies or travelers who must cross rivers quickly.

- Lightweight materials: Make transport and setup simple.

- Structural stability: The design’s strength comes from geometry and friction instead of extra connectors.

Modern tests with scale models and experimental builds show that this approach can work well, even with foundation settlement or changes in load.

Modern Testing and Construction Techniques of the da Vinci Bridge in Real Life

The da Vinci bridge combines historical design with new engineering methods. Modern builders and engineers have tested this self-supporting bridge in labs and outdoor settings to determine its performance and the best materials.

Building Scale Models and Experimental Builds to Test Feasibility

Engineers and students have made many scale models of the Leonardo da Vinci bridge using wooden logs. These experimental builds show that the design holds together using friction and gravity, with no nails or glue.

Some teams, like those at MIT, built miniature versions to measure how much weight the bridge could hold before bending or breaking. They focus on the historical context and the actual drawings da Vinci created.

Testing with models provides insight into practical applications for both large and small spans. Public demonstrations and educational projects also help people understand the mechanical principles and Renaissance engineering behind the structure.

Insights from MIT Engineers on Load-Bearing Capacity and Structural Analysis

MIT engineers conducted a modern testing project on the da Vinci bridge design. They analyzed the structural stability by building a scale bridge that could bear significant loads.

They studied how the arch structure spreads the weight through the bridge and into the abutments at each end. Using sensors, they tracked how stresses moved through the wood.

The team found that da Vinci’s design was ahead of its time, using gravity-based locking to stay in place. Their study showed that the bridge could support a substantial weight, even over a vast space, much like the original Istanbul bridge proposal across the Golden Horn.

Their load-bearing capacity and structural analysis findings displayed real-world feasibility for some modern uses.

Modular Assembly, Quick Assembly, and Disassembly Techniques

The da Vinci bridge uses modular assembly. Each piece interlocks with the next, allowing for quick assembly and disassembly without permanent fasteners.

This feature made the bridge especially useful during the Renaissance era for military or emergencies. Modern builders can complete construction quickly by laying beams in a specific order.

The structure’s mechanical principles help keep the bridge secure and strong. Some educational groups show how a team can assemble the bridge or take it down in less than one hour.

This offers an advantage over traditional suspension bridge construction, which can take much longer.

Use of Lightweight Materials and Timber Construction in Modern Builds

Most modern da Vinci bridge attempts still use timber construction. Wood is light, flexible, and easily shaped into the beams needed for an arch structure.

Builders sometimes use engineered wood products for extra strength or lighter weight. Some experimental builds explore other lightweight materials, like aluminum tubes, to compare how these affect the bridge’s performance.

Using lightweight beams makes moving and assembling the bridge easier, especially for public demonstrations or temporary crossings. The mechanical principles behind the wooden, self-supporting bridge remain true to Leonardo da Vinci’s original engineering innovation.

Challenges of Settlement of Foundations and Durability in Real-World Applications

One challenge with building the da Vinci bridge in real life is the settlement of the foundations. Uneven ground or shifting soil at the abutments can cause the bridge to tilt or become unstable.

MIT’s testing showed that while the historical design is strong, it is also sensitive to movement below the arch, raising questions about durability.

Wooden bridges require regular inspection and maintenance, especially if exposed to rain, snow, or heavy loads. Engineers must consider making the da Vinci bridge safe for daily use and restoring or protecting it from weather and wear.

Practical Applications and Future Prospects of the da Vinci Bridge in Real Life

The da Vinci bridge stands out in real life because of its unique self-supporting structure and its use of wooden logs without nails or glue. Recent studies, public demonstrations, and major proposals demonstrate its relevance to historical and modern engineering.

The Istanbul Bridge Proposal and the Golden Horn Span Project

Leonardo da Vinci designed a bridge proposal in 1502 for Sultan Bayezid II of the Ottoman Empire. If built, this bridge, with a single arch stretching 280 meters, would have spanned the Golden Horn in Istanbul.

This was an ambitious engineering challenge for its time. The design featured an elegant arch structure that relied on gravity and friction for structural stability.

Although the original bridge was never constructed, the concept remained influential. In 2001, builders constructed a smaller-scale model in Norway, following the same principles of modular assembly and self-supporting architecture.

The Istanbul bridge proposal emphasized Renaissance engineering ingenuity. It showed the feasibility of constructing long spans using techniques that required no nails or glue.

MIT engineers’ detailed analysis has shown that the design could have handled the load-bearing capacity needed for large spans. Learn more about the Golden Horn span proposal.

Comparing the da Vinci Bridge with Modern Suspension Bridge Designs

Modern suspension bridges use cables anchored to towers and abutments. This system allows for great spans and flexibility.

The da Vinci bridge relies on friction and gravity to lock wooden logs together. It is self-supporting without external fasteners.

This simple construction makes the bridge easy to assemble and disassemble using lightweight materials. Compared to modern bridges, the da Vinci bridge costs less and needs minimal tools.

However, it cannot match contemporary suspension designs’ span, reach, or adaptability. Its design shows an early understanding of structural analysis and mechanical principles.

Builders must pay close attention to the bridge’s scale, foundation settlement, and local materials.

Public Demonstrations and Educational Projects Showcasing the Bridge

Public demonstrations and educational projects worldwide bring the da Vinci bridge to life. Students and engineers build scale models with timber logs to explore the mechanical principles of friction and gravity.

These hands-on builds show how quickly people can assemble and disassemble the bridge. The process highlights modular assembly.

Events often invite the public to walk across the finished bridge. This proves its practical use and load-bearing ability.

Museums and schools use these projects to teach about architectural ingenuity and the evolution of bridge design. Videos and guides make public demonstrations accessible and encourage more participation.

Engineering Innovation and Real-World Feasibility of the Bridge Design

The da Vinci bridge stands out for supporting weight without traditional fasteners. Builders use only timber and careful geometry.

MIT engineers have tested full-scale and experimental builds. They confirmed the bridge’s durability and efficiency through modern testing.

This structure depends on foundation settlement and gravity-based locking, not glue, bolts, or metal. Choosing lightweight but strong materials improves real-world feasibility.

The bridge is easy to transport and works well for temporary or emergency crossings. Longer spans require careful structural analysis for stability and safety.

The Bridge’s Legacy in Bridge Restoration and Contemporary Bridge Design

Leonardo da Vinci’s design inspired bridge restoration and the construction of a new bridge. Planners study his work for ideas that balance stability, simplicity, and visual appeal.

Engineers use the self-supporting principle to restore historic timber bridges and build new pedestrian crossings. Modern architects adapt the da Vinci approach to eco-friendly or quickly built spans, especially in parks and rural areas.

Educational programs and public exhibits keep the bridge’s legacy alive. Renaissance engineering still guides innovation and practical applications today.

Frequently Asked Questions

The da Vinci bridge is known for its unique self-supporting structure, which inspires engineers and hobbyists. Many people are interested in its history, principles, and real-world applications.

Was the Da Vinci bridge ever used?

Leonardo da Vinci designed the bridge in 1502, but it was never built during his lifetime. His plans showed a bridge meant for the Golden Horn in Constantinople.

Modern engineers have built working models to test whether the design works. Tests have shown that it can be made and used today.

What is the principle behind the Da Vinci bridge?

The Da Vinci bridge uses the weight of each beam to keep the whole structure stable. The design does not need any nails, rope, or glue.

Friction and gravity keep it standing. This makes the bridge easy to build and take apart.

How much weight can the Da Vinci bridge hold?

The weight capacity depends on the materials and size of the beams. In tests with scaled-down models, the bridge has supported the weight of several people at once.

The exact weight capacity in a full-scale version depends on engineering calculations and the choice of material. Modern builds have shown that the design is sturdy when built correctly.

What is the bridge of safety, Leonardo da Vinci?

The “bridge of safety” refers to Leonardo’s self-supporting bridge design. It was meant for rapid disassembly in dangerous situations, such as wartime retreats.

The design allowed soldiers to cross rivers quickly without leaving a permanent structure behind.

How far can a DaVinci bridge span?

Leonardo’s original bridge design was supposed to span 240 meters over the Golden Horn. This was very ambitious for the time.

Today, models can be built with much smaller spans at home. Larger versions are possible using strong modern materials.

Where was Da Vinci buried?

Leonardo da Vinci died in 1519 and is buried in the Chapel of Saint-Hubert at the Château d’Amboise in France.

Why is the Da Vinci Bridge so strong?

The design spreads force across all its beams, making the bridge stable. The self-supporting form uses both compression and friction.

This clever use of simple physics lets the bridge work without fasteners.

What was the most famous bridge that was never built?

Leonardo da Vinci’s bridge over the Golden Horn was the most famous one, but it was never built. Although the design was advanced, it was not constructed until centuries later.

Modern engineers have recreated models based on his sketches.

Why was the Devil’s Bridge built?

Devil’s bridges were built throughout Europe to cross dangerous or difficult parts of rivers and gorges. Legends say these bridges were constructed with the devil’s help because engineering was so advanced.

They are not related to da Vinci’s work.

Is there a bridge in the Mona Lisa?

There is a bridge in the background of the Mona Lisa painting.

Some art historians believe it may show a real Italian bridge, while others see it as a symbolic or imagined structure.

The bridge does not relate to Leonardo’s self-supporting bridge design.

Leonardo Bianchi,

the creator of Leonardo da Vinci's Inventions.

Thank you for visiting

Leonardo Bianchi,

the creator of Leonardo da Vinci's Inventions.

Thank you for visiting