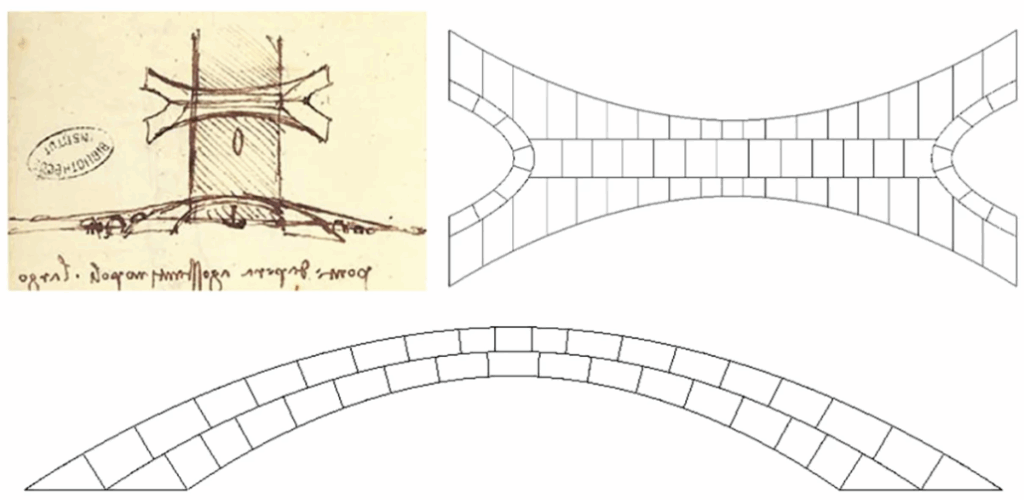

Da Vinci’s bridge design still fascinates engineers and architects, even after five centuries have passed since Leonardo first sketched his bold ideas.

When the Renaissance master proposed his ambitious bridge for the Ottoman Empire in 1502, he laid out engineering principles that were far ahead of their time.

Modern research suggests that Leonardo’s self-supporting bridge design would have been feasible using materials available in the 16th century. Its core concepts continue to inspire sustainable construction and inventive engineering solutions today.

MIT engineers recently demonstrated the structural soundness of Leonardo’s vision. Contemporary architects continue to weave their design philosophy into eco-friendly projects.

The bridge’s elegant balance of form and function shows how Leonardo’s engineering genius crosses historical boundaries. From earthquake-resistant structures to 3D-printed components, his 500-year-old innovations continue to shape modern construction.

The lasting relevance of da Vinci bridge design lies in its blend of artistic beauty and practical engineering. Leonardo’s approach to solving complex structural challenges—utilizing compression, geometry, and material efficiency—still offers valuable lessons for today’s engineers.

The Timeless Engineering Principles Behind Da Vinci Bridge Design

Da Vinci’s bridge design showcases revolutionary engineering ideas that remain surprisingly fresh. The structure relies on compression-only forces, earthquake-resistant foundations, and clever arch geometry, which modern engineers continue to study.

Self-Supporting Structure Without Fasteners or Mortar

The self-supporting bridge design relies solely on compression to maintain its integrity. No nails, glue, or permanent joints hold the wooden beams in place.

The bridge depends on interlocking members that create friction between parts. Each beam fits into place through calculated angles and weight distribution.

This woven design enables the structure to withstand heavy loads without requiring external fasteners. MIT engineers tested this idea with a 1:500 scale model using 126 blocks.

Their research showed that gravity-supported masonry construction would have worked back in 1502. Inserting the keystone creates the final compression lock, which stabilizes the entire span.

Modern emergency bridges still use similar principles. Military teams can deploy bridges quickly without specialized hardware or adhesives.

Flattened Arch Innovation in Modern Bridge Engineering

Leonardo’s flattened arch concept stood out from the usual Renaissance semicircular arches. Most masonry bridges of that time required 10 or more piers for long spans.

His single massive arch would have stretched 280 meters without intermediate supports. The parabolic arch shape spreads loads more efficiently than traditional designs.

This geometry enables greater spans while maintaining stability through the power of geometry, rather than relying solely on material strength. Contemporary bridge engineers see this principle in modern cable-stayed and suspension bridges.

The flattened profile reduces material needs and maximizes span. Current bridges crossing expansive waterways still use similar load distribution ideas.

The design gave 43 meters of vertical clearance for ships passing underneath. That kind of height planning still matters today when designing bridges for shipping channels.

Earthquake Resistance Through Spread Footings

The bridge featured abutments that splayed outward on both sides, kind of like a subway rider widening their stance for balance. These spread footings enhance stability against lateral movement and foundation settlement.

Leonardo noticed the seismic activity in the Golden Horn region and incorporated earthquake-resistant features. The splayed foundation spreads horizontal forces more effectively than vertical supports can.

MIT tests confirmed this seismic stability with foundation movement simulations. Researchers moved the bridge platforms apart to mimic earthquake conditions.

The structure flexed slightly but remained intact until it was pushed to the point of extreme displacement. Modern bridge foundations in earthquake-prone areas continue to employ the principles of spread footing.

Engineers know that foundation design is key to a bridge’s resilience during earthquakes.

Load Distribution and Compression Forces

The bridge transfers all its structural loads through compression forces rather than tension. This eliminates the need for materials strong in tension, allowing builders to use stone for a 280-meter span.

The arch shape naturally channels weight toward the foundations. Each block helps stabilize the whole structure by directing loads downward and outward.

Structural analysis shows how the geometry prevents bending and shear forces that usually lead to bridge failures. The arch turns all loads into manageable compression stresses.

Modern masonry and concrete arch bridges still use these load distribution tricks. Engineers know that innovative geometry can avoid nasty stress concentrations.

Portable and Emergency Military Applications

Leonardo designed this military bridge for quick deployment across rivers or streams. The interlocking design allows builders to assemble it quickly, with no need for special tools or permanent installation.

Soldiers could use local timber and basic carpentry skills. No mortar mixing or fastener installation slows down construction during military operations.

Modern military engineering continues to value portable bridge designs for emergencies. The self-supporting concept enables temporary crossings that can withstand heavy loads without requiring permanent foundations.

STEM challenges and Boy Scout projects demonstrate how simple materials, such as craft sticks, can be used to create working models. This hands-on approach makes the design handy for emergency response and temporary infrastructure.

Modern Applications and Educational Value of Da Vinci Bridge Design

Da Vinci bridge design has earned real-world validation through MIT’s rigorous testing. It has been showcased in Norway as a pedestrian bridge and serves as a creative STEM education tool worldwide.

The design has grabbed international media attention and sparked a network of bridge projects that demonstrate Leonardo’s lasting engineering principles.

MIT’s Groundbreaking 3D Printing Validation Study

MIT engineers analyzed Leonardo da Vinci’s bridge design and demonstrated that it would have been feasible using only the materials and methods available during the Renaissance era.

Graduate student Karly Bast, along with Professor John Ochsendorf and undergraduate Michelle Xie, built a detailed 1:500-scale model using 3D printing.

The team spent six hours printing all 126 blocks for their 32-inch model. They used no fasteners or mortar, relying only on compression forces—just as Leonardo intended.

Key findings from the MIT study:

- The bridge stayed stable under normal loads

- It held up to foundation movement and seismic activity

- The power of geometry made the self-supporting structure possible

- Leonardo’s design was “well thought out” and showed his grasp of structural engineering

The team shared their results at the International Association for Shell and Spatial Structures conference in Barcelona. Their work also showed up on PBS NOVA, bringing Leonardo’s engineering brilliance to a broader audience.

The Norway Bridge: From Sketch to Reality After 500 Years

Five hundred years after Leonardo’s death, his vision came to life when Norway finished a pedestrian bridge based on his design in 2001. Artist Vebjørn Sand led the Da Vinci Bridge Project, building a 109-meter structure near Ås, Norway.

The Norwegian bridge crosses European route E18 with a 40-meter main span. Built from laminated wood instead of stone, it required modern materials to achieve the ambitious scale Leonardo had envisioned.

Queen Sonja officially opened the bridge, marking the first real-world use of the Renaissance master’s engineering concept.

Bridge specs:

- Total length: 109 meters

- Main span: 40 meters

- Material: Glued laminated timber (glulam)

- Cost: 12 million Norwegian kroner

- Construction method: Prefabricated sections put together by crane

This project showed that Leonardo’s flattened arch design could work as intended. It has inspired further applications of his engineering principles in today’s construction.

STEM Challenge and Educational Demonstrations

The self-supporting bridge has become a favorite hands-on learning tool in engineering education and STEM programs. Students build scale models using simple materials, such as craft sticks, garden canes, or construction lumber, to grasp fundamental structural principles.

Educational demos focus on the bridge’s core concepts: compression-only forces, interlocking members, and geometric stability. The project demonstrates to students that design—rather than fancy materials or connections—brings strength.

Common educational materials:

- Craft sticks or popsicle sticks for small models

- 2×6 lumber for larger demos

- Logs with notches for outdoor camp builds

- Garden canes for lightweight classroom versions

Boy Scout groups and engineering camps often use the Da Vinci Bridge as a pioneering project. The DIY construction allows students to experience the same principles that Leonardo applied to his original 1502 design for Sultan Bayezid II.

Global Public Art Project and International Bridge Network

Leonardo’s bridge concept has sparked several international installations as part of a growing global public art network. Projects have emerged in various locations, from Antarctica to Greenland, each adapting the design to local conditions and materials.

Notable installations include ice sculptures in Queen Maud Land, Antarctica, and temporary bridges in Copenhagen during the COP15 climate conferences. These projects show the universal appeal of Leonardo’s engineering ideas across cultures and environments.

The international bridge network emphasizes the use of local materials and artisans, staying true to Leonardo’s practical approach. Each installation serves as both an art and an engineering demo, proving how Renaissance innovation still matters in modern design challenges.

Media Recognition and International Attention

Major news outlets have featured the Da Vinci bridge design, bringing Leonardo’s engineering legacy to global audiences.

CNN covered MIT’s validation study, highlighting how the 500-year-old design passed modern structural analysis.

The Wall Street Journal, National Geographic, and The Guardian have all published articles about the bridge’s significance.

Some publications have even called it one of the “five coolest bridges on Earth,” acknowledging its historical significance and its surprising modern relevance.

Media coverage highlights:

- Engineering feasibility and structural innovation

- Historical significance of Leonardo’s Universal Genius

- Modern applications in education and public art

- Integration of art and engineering principles

This widespread attention has sparked renewed interest in Leonardo’s engineering notebooks and manuscripts.

The coverage shows that fancy technology isn’t always necessary for groundbreaking design concepts.

Why Leonardo’s Renaissance Engineering Genius Matters in the 21st Century

Leonardo da Vinci’s engineering principles still shape modern construction. He understood structural geometry and compression forces on a level that remains impressive even now.

His blend of artistic vision and mathematical precision offers valuable lessons for designers seeking sustainable solutions.

Historical Significance and Lost Knowledge Rediscovered

Renaissance engineering marked a time when scientific observation merged with hands-on construction.

Leonardo’s bridge design, proposed in 1502 to Sultan Bayezid II for the Golden Horn in Istanbul, remained forgotten for 400 years until it was rediscovered in 1952.

The proposal would have created the world’s longest bridge span at 280 meters, with a 240-meter main section. That was ten times longer than the bridges of its day.

Researchers at MIT validated his structural concepts with scale model testing.

MIT engineers Karly Bast and John Ochsendorf demonstrated that a self-supporting bridge could be constructed using only compression forces and interlocking members.

Form and Stability Relationship in Contemporary Design

The flattened arch geometry shows how structural form influences stability, with no modern fasteners or mortar required.

Leonardo’s pressed bow arch distributes loads through pure compression, cutting out tension forces that often cause failure.

Engineers today study his parabolic arch ideas for earthquake-resistant structures.

The bridge’s method of handling lateral sway and foundation movement—utilizing spread footings and abutments that splay outward—still offers valuable insights for seismic zones.

MIT’s 1:500 scale model, which utilized 126 blocks, confirmed the design’s structural integrity.

The keystone insertion method and load distribution patterns show how Renaissance engineers understood compression-only structures.

Art and Engineering Integration for Modern Designers

Leonardo erased the line between artistic vision and technical execution. His notebook drawings in Manuscript L show how aesthetics can actually boost structural performance.

The geometric power in his designs reminds modern architects that structure is the architecture.

This philosophy inspires bridge designers who seek elegant solutions that are both functional and aesthetically pleasing.

Modern engineering still references Leonardo’s mathematical precision in structural analyses.

His blend of rational analysis and wild imagination provides a model for innovation.

From Classical Masonry to Modern Construction Techniques

The masonry bridge concept, featuring thousands of stone blocks, embodies timeless principles that align with today’s materials.

Leonardo envisioned stone construction, but modern versions utilize steel and concrete, while retaining his geometric principles.

Norway’s 2001 project used laminated wood and glued laminated timber—a cool update. The 40-meter main span pedestrian bridge cost 12 million Norwegian kroner and was built with prefabricated sections assembled by crane.

Contemporary masonry techniques still utilize Leonardo’s principles of compression forces and interlocking members for earthquake-resistant construction—no mortar is needed.

Inspiring Future Generations Through Renaissance Innovation

Educational programs around the world use the da Vinci bridge design for STEM challenges and engineering demos.

Students build models with craft sticks, garden canes, and construction lumber to learn about structural deformation and load capacity.

This simple yet sophisticated approach shows that fancy technology isn’t always needed for innovation.

That message encourages young engineers to think creatively about sustainable construction and utilize local materials.

Leonardo’s work feels more relevant today than during the Renaissance, inspiring climate change awareness projects and international bridge networks that teach engineering through hands-on learning.

Frequently Asked Questions

Leonardo da Vinci’s bridge design utilizes self-supporting wooden beams that interlock without the need for nails, glue, or rope.

The structure relies on compression forces and weight distribution to stay stable and strong.

What is the Davinci method of bridge?

The Da Vinci bridge method uses interlocking wooden beams that support each other through compression.

No fasteners, nails, or mortar hold the pieces together.

Each beam locks into place with the others. The weight of the structure holds everything together.

This creates a self-supporting bridge that can be built relatively quickly.

How did Da Vinci design his bridge?

Da Vinci created his self-supporting bridge design in the late 15th century for military use.

He drew the plans as part of his engineering work during the Renaissance.

The design uses wooden logs arranged in a pattern. Each piece fits with the others to make a stable crossing.

Da Vinci created detailed sketches illustrating how the beams should be connected.

What is the theory of the Davinci Bridge?

The theory behind the Da Vinci bridge centers on compression and load distribution.

Weight from above pushes down on the interlocked beams, causing them to grip each other more tightly.

The interlocking mechanism distributes weight evenly across the structure.

This prevents any single beam from carrying too much load. The more weight you add, the stronger the connection gets.

What is the principle of the Da Vinci bridge?

The primary principle is that all forces are transferred through compression only.

The beams press against each other to create stability, so you don’t need external binding materials.

Gravity pulls the structure down, but the interlocking design redirects these forces.

The beams support each other in a balanced system, and each piece depends on the others to stay in place.

What are the disadvantages of the Da Vinci bridge?

Modern materials and building methods offer better choices for bridges.

Today’s designs offer numerous options for lighter and stronger bridges.

The Da Vinci bridge requires precise alignment for all its components.

If one beam shifts or fails, the whole structure might collapse. The design also requires specific types of wood and careful preparation of the materials.

What is the rule of 7 in bridge?

The rule of 7 is commonly applied in card games and competitive bridge. It has nothing to do with Da Vinci’s physical bridge design.

Da Vinci’s bridge works on engineering principles. His wooden bridge relies on compression forces and how the weight spreads out, not on any card game strategy.

Leonardo Bianchi,

the creator of Leonardo da Vinci's Inventions.

Thank you for visiting

Leonardo Bianchi,

the creator of Leonardo da Vinci's Inventions.

Thank you for visiting