Leonardo da Vinci’s bridge design continues to captivate architects, even after 500 years have passed.

Da Vinci’s bridge design continues to fascinate engineers, sparking projects from Norway to research at places like MIT.

Back in 1502, the inventor proposed his ambitious bridge for the Ottoman Empire. He introduced engineering ideas that were, frankly, centuries ahead of their time.

The design had a single, flattened arch spanning 280 meters. That would have made it the longest bridge in the world at the time.

The Genesis of Revolutionary Design (Rising Action)

Leonardo da Vinci’s bridge design emerged from military needs and bold ambition. He challenged old-school engineering with geometric principles and self-supporting structures.

When Sultan Bayezid II Challenged Renaissance Genius

In 1502, Sultan Bayezid II set an extraordinary challenge for Renaissance engineers. He wanted a bridge to span the Golden Horn, linking Istanbul and Galata across a tricky waterway.

The task was daunting. Bridges then needed many piers and semi-circular arches, but the Golden Horn’s width and ship traffic demanded something new.

Leonardo’s answer was so futuristic it got rejected. He pitched a single-span bridge, 240 meters long—ten times longer than bridges of his day.

Leonardo’s Golden Horn Bridge Proposal for Istanbul

The Golden Horn bridge proposal showcased its double-curvature arch. Unlike the usual arches, this flattened design allowed ships to pass and spanned huge distances.

He described it as “as tall as a building,” letting ships sail underneath. The bridge would have linked two continents using a gravity-based masonry system—no typical supports needed.

Scientists eventually proved the bridge could work. It turns out that Leonardo’s gut instincts about structure were way ahead of his time.

From Military Engineer to Architectural Visionary Under Cesare Borgia

Working as a military engineer for Cesare Borgia shaped Leonardo’s bridge ideas. He devised emergency bridges for troops, prioritizing speed and stability.

His revolving bridge was meant for fast troop movement across water. These temporary bridges had to be portable and tough enough for battle.

Military needs drove him to get creative. He designed bridges that could be assembled without special tools or permanent foundations, which led to his self-supporting arch ideas.

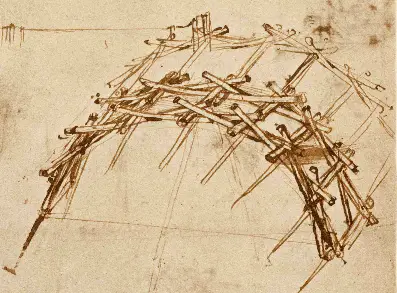

The Self-Supporting Arch That Defied Convention

Leonardo’s self-supporting bridge was a real departure from the norm. It required no nails, ropes, or fasteners, yet remained stable thanks to its interlocking parts.

The system balanced compression and tension. Each wooden beam supported the others through careful geometry, spreading the weight across the entire structure.

Key features of the self-supporting arch:

- Interlocking wooden beams

- No mechanical fasteners needed

- Gets stronger under load

- Quick to put up and take down

Geometric Principles That Changed Bridge Construction Forever

Leonardo’s bridge sketches introduced math concepts that wouldn’t be formalized for centuries. He just seemed to “get” three-dimensional equilibrium and used it to build stable structures from pure geometry.

Modern computational analysis reveals that Leonardo employed design principles that were not developed until 400 years after his time. His approach to weight distribution made his bridges stronger as the load increased.

He placed the keystone and shaped the arch with an understanding of forces that structural engineers wouldn’t fully document until much later.

The Ingenious Mechanics Behind Leonardo’s Vision (Climax)

Leonardo da Vinci’s bridge design shook up structural engineering. He utilized compression, interlocking geometry, and gravity-supported masonry—eliminating the need for fasteners. The flattened arch distributes weight through a double-curvature system, striking a balance between strength and style.

How Compression and Tension Forces Create Structural Stability

Leonardo understood how arches handle compression and tension. His design pushed the weight down through the stone blocks, causing them to press against each other.

The flattened arch made the bridge stable by turning vertical loads into horizontal thrusts. Each stone transferred its weight to its neighbors through compression.

Key Force Distribution:

- Vertical loads from the deck

- Horizontal thrust at the arch supports

- Compression between stone joints

- Minimal tension stress throughout

The geometry made sure no single block took too much weight. The arch shape spreads the load evenly.

The Interlocking Structure with No Nails, Ropes, or Fasteners

The interlocking structure skipped nails, ropes, or fasteners. Leonardo made each stone fit its neighbors like a 3D puzzle.

Physical contact and geometric constraints held it all together. Stones couldn’t move because the others blocked them from every angle.

Assembly Requirements:

- Temporary wood scaffolding

- Precisely cut stones

- Place stones from supports toward the center

- Insert the final keystone to finish

The self-supporting bridge dodged problems with failing fasteners. Stone-to-stone contact made connections that could last for centuries.

Weight Distribution Through the Flattened Arch Design

The flattened arch spreads loads across a wide span, not just a few points. That reduced stress on each part.

Leonardo’s arch rose just enough for sailboats but spanned the Golden Horn’s 280 meters. The shallow curve sent loads efficiently to the foundations.

Old-school semicircular arches would have required numerous piers in the water. The flattened shape eliminated those issues, thanks to improved weight distribution.

Gravity-Supported Masonry and the Critical Keystone Placement

Gravity-supported masonry depended on the keystone at the top. That final wedge-shaped stone locked everything in place.

MIT researchers found that squeezing in the keystone put the whole arch under compression. That initial stress held it all together.

Before the keystone, wooden scaffolding supported the stones. Once the keystone was in, removing the supports tested whether the geometry alone could keep the arch standing.

Balance and Ingenuity in the Double-Curvature Arch System

The double-curvature arch really showed Leonardo’s knack for problem-solving. The arch curved vertically and horizontally to handle different forces.

Vertical curves were designed to handle the weight from traffic and the bridge itself. Horizontal curves helped prevent sideways collapse during earthquakes or strong winds.

Leonardo’s plan for Sultan Bayezid II even had splayed abutments—wider foundations for more stability. That was a smart move for earthquake-prone Istanbul.

From Renaissance Era Dreams to Modern Architectural Reality (Falling Action & Resolution)

Leonardo da Vinci’s bridge design began as a 16th-century dream but evolved into a proven engineering achievement. Today, modern research and bridges around the world show his lasting impact on design.

Why the Emergency Bridge for Troops in Times of War Was Never Built

Leonardo da Vinci conceived his famous bridge in 1502 for Sultan Bayezid II, aiming to span the Golden Horn near Istanbul. The design would have set a record at 280 meters.

Politics got in the way. Leonardo was working for Cesare Borgia as a military engineer. His emergency bridge idea didn’t use nails, ropes, or fasteners—perfect for quick troop movements in wartime.

The Sultan ultimately rejected Leonardo’s radical design. Why? Well, there were a few reasons:

- Scale concerns: The bridge was 10 times longer than anything else back then

- Unproven technology: The self-supporting arch seemed too risky

- Construction complexity: Nobody really knew how to build something that big with the tools they had

- Political instability: Ongoing wars made giant projects tough to pull off

So, Leonardo’s bold flattened arch design stayed on paper for centuries.

MIT Proves the Temporary Structure Could Have Worked

Recent MIT researchers showed that Leonardo’s bridge design was structurally sound through hands-on testing. Graduate student Karly Bast and her team built a 1:500 scale model using 126 3D-printed blocks.

The gravity-supported masonry design relied entirely on compression and tension forces. No mortar or fasteners held the structure together.

The team placed the keystone, and the bridge stood securely in place. The model even withstood simulated earthquake conditions.

Leonardo had added spread footings for extra stability, demonstrating his understanding of the region’s seismic risks. The research showed that geometric principles and weight distribution enabled the design to be constructed using Renaissance-era materials and methods.

Norway’s Pedestrian Bridge Brings Leonardo’s Vision to Life

Modern engineers have built bridges inspired by Leonardo’s ideas, though they use steel and concrete instead of stone. A pedestrian bridge in Norway shows how his interlocking structure principles work in real life.

The Norwegian bridge proves Leonardo’s basic design works. Still, modern materials can’t really test whether his original stone masonry would have held up with the tools of his time.

How Modern Architects Apply Leonardo da Vinci Bridge Design Principles

Contemporary architects utilize Leonardo’s concepts of structural stability in large-scale projects. His knack for balance and ingenuity in self-supporting structures continues to influence bridge engineering today.

Some key principles that stick around include:

- Double-curvature arch designs for spanning big distances

- Load distribution through compression, not tension

- Earthquake-resistant foundations

- Single-span solutions for tricky landscapes

Modern architectural marvels, such as the Sydney Harbor Bridge, borrow ideas from Renaissance-era innovations.

The Lasting Legacy of the Self-Supporting Bridge in Contemporary Engineering

Leonardo’s self-supporting bridge concept demonstrates how Renaissance thinking continues to influence engineering. His grasp of structural forces developed long before he received formal engineering education.

Contemporary bridge designers still look to his creative approaches for tough spans. The idea that geometric principles can create stable structures without the need for complicated fasteners remains relevant.

Frequently Asked Questions

Leonardo da Vinci’s bridge design utilizes self-supporting wooden beams that interlock without the use of nails, glue, or mortar. The structure relies on compression forces and geometric principles that engineers continue to study.

Did Leonardo da Vinci design a bridge?

Leonardo da Vinci designed a groundbreaking bridge in 1502 for Sultan Bayezid II of the Ottoman Empire. The bridge was meant to span the Golden Horn in Istanbul.

His design would have created the world’s longest bridge at 280 meters. That was ten times longer than most bridges of that time.

The Sultan rejected the idea because it seemed too ambitious for the technology available at the time. Leonardo’s sketches remained hidden until they were rediscovered by researchers in 1952.

What is the Davinci method of bridge?

The Da Vinci bridge method uses interlocking wooden beams that support each other through compression. No fasteners, nails, or mortar hold the pieces together.

Each beam locks into place with the others thanks to careful angles and weight distribution. The structure creates sufficient friction between its parts to maintain stability.

This design enables soldiers or builders to assemble bridges quickly using local timber. The bridge can handle heavy loads without special tools or permanent foundations.

What is the science behind the Da Vinci bridge?

The science focuses on compression-only forces and load distribution through geometric design. Weight from above pushes down on the interlocked beams, making them grip each other more tightly.

The flattened arch shape spreads loads more efficiently than traditional semicircular designs. This geometry converts all forces into manageable compression, rather than tension.

MIT engineers tested a 1:500 scale model using 126 blocks to prove the concept works. Their research confirmed the bridge would have been structurally sound using Renaissance materials.

What is the history of the Da Vinci Bridge?

Leonardo designed the self-supporting bridge in the late 15th century for military uses. The design was part of his larger body of engineering work during the Renaissance.

He proposed the bridge to the Ottoman Empire in 1502 as a permanent crossing. The ambitious 280-meter span would have been a marvel of engineering for its time.

After centuries of being forgotten, Norway built the first major bridge using da Vinci’s design in 2001. This pedestrian bridge near Oslo proved his engineering concepts could work in practice.

How strong is Da Vinci’s bridge design?

MIT testing demonstrated that Leonardo’s bridge design can withstand normal loads and accommodate foundation movement. The compression-only structure stays stable even during simulated earthquakes.

The interlocking beam system spreads weight evenly across the whole structure. No single piece carries too much load, so there aren’t obvious failure points.

The design’s strength stems from its geometry, not from fancy materials. Builders can use simple wood or stone to make surprisingly strong spans.

Is Da Vinci’s bridge design still used today?

Da Vinci’s bridge design continues to appear in the work of modern engineers and architects. You can spot his compression-only ideas in some earthquake-resistant structures today.

Military engineers often use similar self-supporting concepts for emergency bridges. These temporary crossings are quick to set up and don’t require special hardware or a permanent installation.

Schools and educational programs worldwide utilize this design for STEM challenges. Students build models from simple materials, gaining a fundamental understanding of structural principles and how loads are transferred through a bridge.

Leonardo Bianchi is the founder of Leonardo da Vinci Inventions & Experiences, a travel and research guide exploring where to experience Leonardo’s art, engineering, and legacy across Italy and Paris.

Leonardo Bianchi is the founder of Leonardo da Vinci Inventions & Experiences, a travel and research guide exploring where to experience Leonardo’s art, engineering, and legacy across Italy and Paris.